- Primary Culprit: Over 70% of steering wheel vibrations during braking are caused by Disc Thickness Variation (DTV)—commonly referred to as warped brake rotors.

- The Brake Pedal Clue: If vibration is felt in both the steering wheel and brake pedal, the problem almost always originates in the front braking system.

- Beyond the Brakes: Worn suspension components—especially control arm bushings, tie rods, and ball joints—can amplify shaking under braking loads.

- 2026 Tech Warning: Modern brake-by-wire and ADAS systems may partially mask pedal feedback, delaying detection of early signs of warped brake rotors.

- Safety First: Steering wheel shake reduces consistent tire-to-road contact and can increase emergency stopping distances by up to 25%.

Introduction: The Pulse of Automotive Safety

You’re cruising at highway speed. Traffic slows ahead, you gently apply the brakes—and suddenly the steering wheel begins to pulse, shimmy, or vibrate in your hands. The sensation is unmistakable and unsettling. In that moment, one question dominates every driver’s mind: Is my vehicle still safe to drive?

Steering wheel shake during braking is not just an annoyance—it is a mechanical warning signal. Your vehicle is communicating that something in the braking, steering, or suspension system is no longer operating within design tolerances. In modern vehicles, where braking performance is tightly integrated with electronic stability control, adaptive cruise control, and automatic emergency braking, these vibrations carry even greater significance.

Recent 2025 consumer and service-industry reports show that braking-related vibration accounts for nearly 30% of all non-routine brake service visits. Even more concerning, braking defects remain a top-three cause of mechanical-related road incidents worldwide. Vehicles older than five years face an increased risk: each year of service adds roughly 15% higher likelihood of brake-induced oscillation, driven by heat cycling, corrosion, and material fatigue.

Identifying the root cause early is essential—not only to avoid escalating repair costs, but also to maintain predictable stopping power. In many cases, vibration is the first visible symptom of the 5 Telltale signs of warped brake rotors“, a condition where uneven rotor thickness causes the brake pads to repeatedly grip and release as the wheel rotates.

This 2026 diagnostic guide breaks down the mechanical failures—from brake rotors to suspension bushings—that cause steering wheel shake when braking. More importantly, it equips you with the technical language needed to communicate clearly with technicians and avoid unnecessary repairs.

1. The Anatomy of a Shake: Is It Brakes, Tires, or Suspension?

Not all vibrations mean the same thing. The location, timing, and intensity of the shake provide valuable diagnostic clues.

The “Pedal vs. Wheel” Diagnostic Test

Where you feel the vibration matters:

- Steering wheel only:

Typically indicates a front-end issue, most commonly front brake rotors, front wheel bearings, or alignment-related problems. - Brake pedal and steering wheel:

Strongly suggests front brake disc thickness variation or caliper-related issues. - Seat or floor vibration:

More often linked to rear brakes, driveline imbalance, or rear suspension components.

Because over 70% of braking force is handled by the front axle, front-end problems are far more likely to transmit vibration directly into the steering wheel.

Brake-Induced Vibration vs. High-Speed Shimmy

A critical distinction must be made between braking vibration and speed-related shake:

- Occurs only when braking:

Almost always brake-related—rotors, pads, calipers, or hub surfaces. - Occurs at specific speeds (without braking):

Typically caused by tire imbalance, bent wheels, or alignment issues.

If the vibration disappears the moment your foot comes off the brake pedal, tires are rarely the primary cause.

The 2026 ADAS Factor

Advanced Driver Assistance Systems (ADAS) have changed how vibrations are perceived. Vehicles equipped with:

- Brake-by-wire systems

- Automatic Emergency Braking (AEB)

- Electronic Brake Force Distribution

may filter or dampen pedal feedback, especially at lower speeds. As a result, drivers may feel vibration in the steering wheel before noticing pulsation in the brake pedal—making early signs harder to recognize.

Diagnosing Shaking Based on Driving Scenarios

Not all steering wheel vibrations behave the same way. When and how the shake appears is often more revealing than the vibration itself. These driving scenarios help narrow the failure zone before any parts are replaced.

Steering Wheel Shakes When Braking at High Speeds

When vibration appears above 55–60 mph and intensifies as braking force increases, the most likely causes are rotor runout and high-speed wheel imbalance.

At highway speeds, even microscopic imperfections are amplified. Rotor runout—side-to-side wobble of the brake disc—causes the pads to repeatedly push the caliper pistons back and forth. This oscillation travels through the steering knuckle directly into the steering wheel.

High-speed vibration diagnostics should focus on:

- Excessive lateral runout (often from improper rotor installation)

- Uneven lug nut torque

- Rust scale between the rotor hat and hub

- Previously balanced tires that are now marginal at higher rotational speeds

Unlike tire imbalance alone, brake-induced high-speed shake disappears immediately when braking stops, making this distinction critical.

Steering Wheel Shakes When Braking on the Highway

Highway braking introduces additional variables that don’t exist in city driving. Sustained airflow, aerodynamic drag, and prolonged rotor contact expose weaknesses that remain hidden at lower speeds.

Common highway-specific causes include:

- Tire flat spots, often from long parking periods or emergency braking

- Marginal rotor thickness combined with heat expansion

- Brake pads that operate quietly at low speed but vibrate under higher clamping force

Aerodynamic load at highway speed also increases front-end downforce, intensifying any existing brake or suspension imbalance. This is why some vehicles feel perfectly smooth in town yet shake noticeably during highway deceleration.

Steering Wheel Shakes When Braking Downhill

Downhill braking is one of the most destructive conditions for braking systems. Gravity forces prolonged brake application, causing rapid heat buildup and thermal distortion.

This scenario strongly points to:

- Heat-induced disc thickness variation (DTV)

- Brake fade from overheated pads

- Pad material transfer onto overheated rotor surfaces

Drivers often report that the vibration worsens the longer the downhill descent continues. Once overheated, rotors can develop permanent high spots, resulting in ongoing steering wheel shake even after cooling.

Downhill vibration is one of the clearest early warnings of impending rotor failure.

Steering Wheel Shakes When Braking at Low Speeds

Low-speed braking vibration—especially under 30 mph—is less likely to be rotor-related and more commonly tied to mechanical looseness.

Primary suspects include:

- Worn control arm bushings allowing fore-aft wheel movement

- Sticking or partially seized brake calipers

- Dry or corroded caliper slider pins

At low speeds, braking force transfers directly into suspension joints rather than being smoothed out by rotational momentum. This allows even small amounts of play to become noticeable through the steering wheel.

Low-speed shake is frequently misdiagnosed as a brake issue when the real cause is suspension compliance failure.

Is the Issue Front or Rear? Understanding Vibration Locations

Correctly identifying where the vibration originates prevents unnecessary part replacement and misaligned repairs.

Steering Wheel Shakes When Braking: Front or Rear Rotors?

The human body is a surprisingly accurate diagnostic tool when used correctly.

Front brake vibration characteristics:

- Felt primarily in the steering wheel

- Often accompanied by pedal pulsation

- Steering wheel oscillates left and right

Rear brake vibration characteristics:

- Felt through the seat or floor

- Minimal steering wheel feedback

- Often mistaken for drivetrain issues

The “Seat of the Pants” Test

This informal test remains one of the fastest diagnostic indicators:

- Hands shaking = front-end problem

- Seat shaking = rear-end problem

Because front brakes handle up to 75% of braking force, steering wheel shake overwhelmingly points to front rotors or front suspension components.

Vehicle-Specific Vibration Patterns & Known Issues

Certain vehicle platforms exhibit repeat vibration patterns due to design choices, brake sizing, or suspension geometry.

Why the Mazda CX-5 Steering Wheel Shakes When Braking

The Mazda CX-5 is known for responsive steering but uses relatively lightweight front rotors. In stop-and-go or aggressive driving conditions, these rotors are prone to heat saturation, leading to DTV.

Common contributing factors include:

- Factory pad compound sensitivity to heat

- Urban driving with frequent short stops

- Rotor resurfacing instead of replacement

Upgraded rotors and proper torque procedures significantly reduce recurrence.

BMW X5 Shaking Patterns Under Deceleration

BMW X5 models often exhibit braking vibration tied to:

- Performance-oriented brake compounds

- Aggressive brake bias

- Sensitive steering rack feedback

Even minor rotor imperfections are transmitted through the steering wheel. Additionally, worn thrust arm bushings are a known amplifier, causing shake only during deceleration.

Toyota Camry and Corolla: Common Brake Pulse Diagnostics

These platforms are mechanically robust, but vibration typically arises from:

- Economical aftermarket brake parts

- Improper hub cleaning during rotor replacement

- Uneven pad bedding procedures

In most cases, the issue is installation-related rather than component failure.

While many drivers assume warped rotors are the only cause, Toyota’s Technical Service Bulletin T-SB-0313-17 reveals that improper lug nut torque is a frequent culprit for steering wheel vibration in Camry and Corolla models. This bulletin notes that over-tightening even a single lug nut can cause ‘lateral runout,’ leading to a pulse that mimics a warped disc. For owners of the Tacoma and Tundra, the official Toyota Parts & Service guide recommends checking for heavy-duty thermal stress before replacing components, as these trucks often require specific torque patterns to maintain braking stability under load.

Nissan Titan and Tacoma: Handling Heavy-Duty Brake Load Issues

Trucks experience higher thermal loads due to weight and towing demands. Common issues include:

- Rotor overheating during towing

- Caliper piston sticking from dust and corrosion

- Premature pad glazing

Steering wheel shake in these vehicles often indicates under-spec braking components for actual use conditions.

Subaru and Pontiac G6: Steering Rack vs. Brake Component Failure

Subaru models with symmetrical AWD and Pontiac G6 vehicles share a tendency for:

- Steering rack bushing wear

- Tie rod end play masquerading as brake vibration

In these cases, replacing rotors alone does not resolve the issue, leading to repeat service visits.

Core Mechanical Culprits: Beyond the Symptoms

Understanding symptoms is only half the equation. Identifying root mechanical failures prevents recurrence.

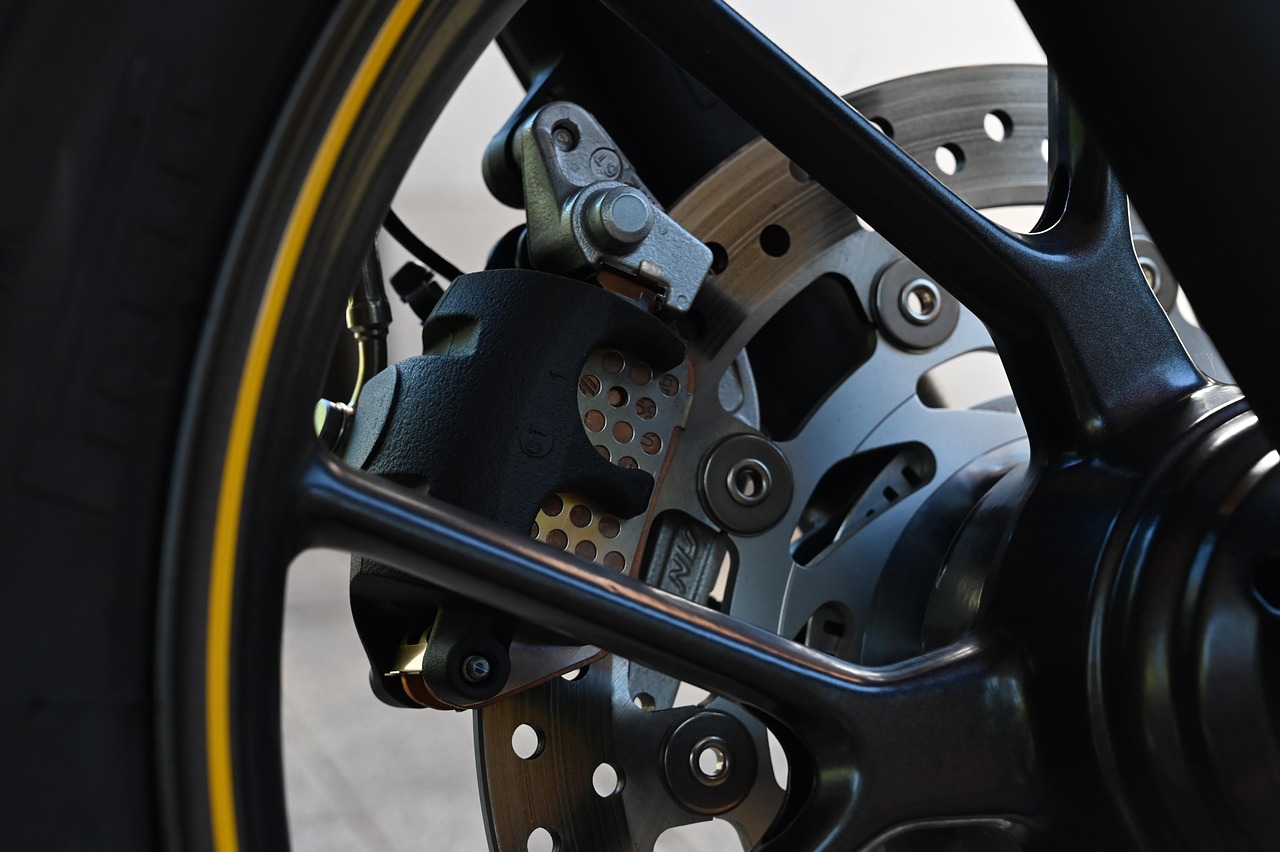

Signs of Warped Brake Rotors: 5 Telltale Indicators

- Steering wheel oscillation during braking

- Brake pedal pulsation that increases with speed

- Vibration that worsens after long or downhill braking

- Uneven pad wear patterns

- Rotor surface discoloration or pad material spotting

These signs of warped brake rotors often appear gradually, making early detection critical.

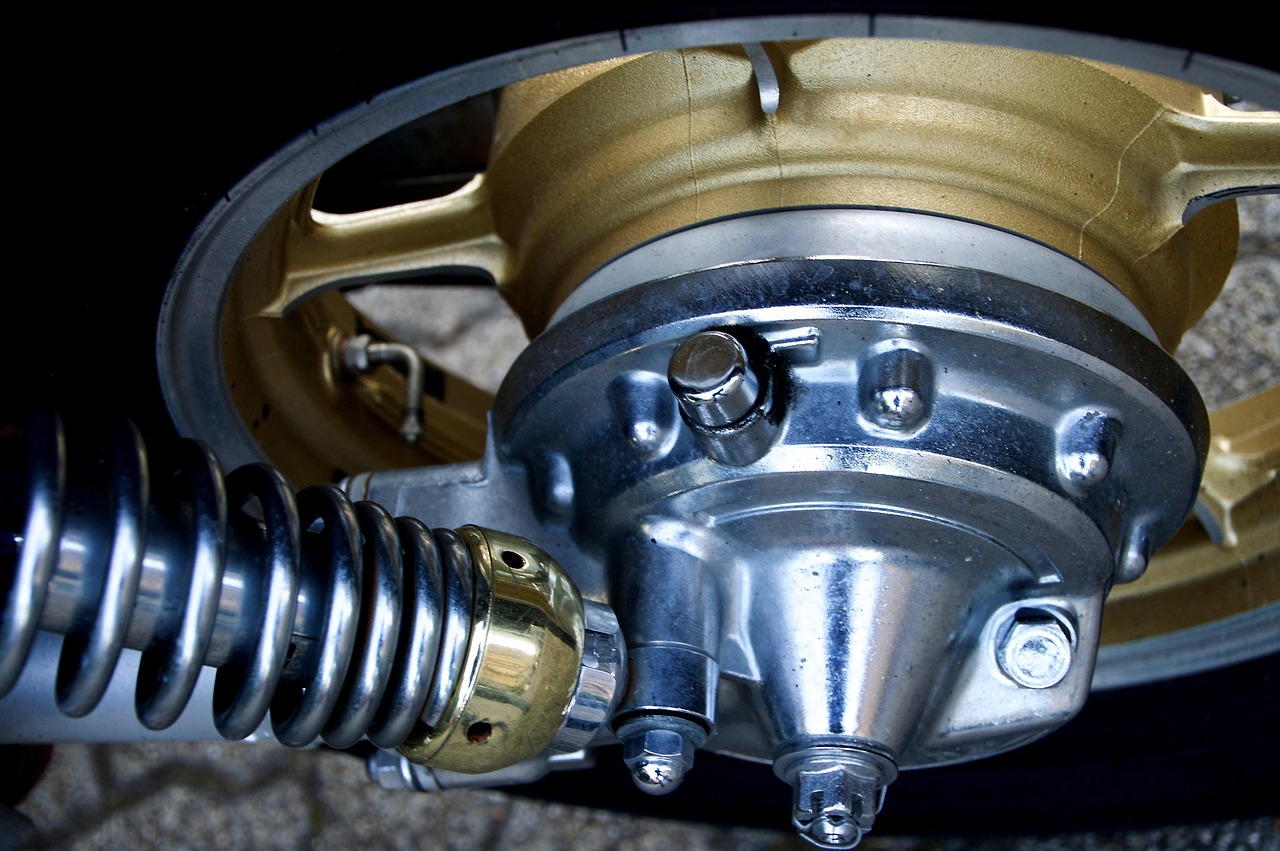

Worn Suspension Bushings and Tie Rod Ends

Suspension components are designed to absorb braking forces elastically. When bushings crack or harden:

- Wheels shift backward under braking

- Toe alignment changes momentarily

- Steering feedback becomes unstable

Tie rod end wear adds directional looseness, compounding vibration already caused by braking irregularities.

Caliper Piston Seizure and Slider Pin Friction

Brake calipers must move freely to apply even pressure. When pistons or slider pins bind:

- One pad drags continuously

- Rotor overheats unevenly

- Steering wheel pulls and shakes under braking

This condition often progresses silently until vibration becomes severe.

Final Diagnostic Insight

When steering wheel shake appears, the vehicle is already past the earliest failure stage. Modern braking systems may mask pedal feedback, but steering vibration remains a reliable indicator of mechanical imbalance.

2. Warped Brake Rotors: The #1 Cause of Steering Wheel Shake

Understanding Disc Thickness Variation (DTV)

Contrary to popular belief, most brake rotors do not physically “warp” like a bent plate. Instead, they develop Disc Thickness Variation—microscopic high and low spots around the rotor’s circumference.

As the wheel rotates:

- Thicker sections push the brake pistons back

- Thinner sections allow them to extend further

- This rapid in-and-out motion creates vibration felt in the steering wheel

Even variations as small as 0.0005 inches can be detected by modern braking systems.

How Rotors Develop DTV

Heat Cycling and Thermal Stress

Repeated heating and cooling causes uneven metal expansion. Common high-risk driving conditions include:

- Stop-and-go city traffic

- Mountain descents with prolonged braking

- Towing or hauling heavy loads

When rotors overheat, they become more susceptible to uneven pad material transfer, which accelerates DTV formation.

The Lug Nut Torque Myth (That’s Actually Real)

Improper wheel installation is one of the most overlooked causes of rotor distortion. Using an impact wrench without a torque stick can:

- Unevenly clamp the rotor to the hub

- Introduce lateral runout

- Permanently deform the rotor during heat cycles

Correct torque—applied in a star pattern using a calibrated torque wrench—is critical.

Glazed Pads and Lateral Runout

Sometimes, the rotor itself is dimensionally sound, but pad material has been unevenly deposited onto the surface. This creates the same sensation as a warped rotor and is often misdiagnosed.

Lateral runout—side-to-side rotor wobble—can also originate from:

- Rust on the hub face

- Debris trapped between rotor and hub

- Manufacturing tolerances stacking up

3. Suspension and Steering: The Hidden Culprits

When brakes apply force, suspension components are placed under extreme forward load. Worn parts that feel fine while cruising can fail dramatically under braking.

Worn Control Arm Bushings

Rubber bushings degrade over time due to:

- Heat exposure

- Oil contamination

- Environmental aging

When braking, weakened bushings allow the wheel to shift backward slightly, creating a flutter or shimmy felt through the steering wheel.

Tie Rod Ends and Ball Joints

Any play in steering linkage is magnified during deceleration. Symptoms include:

- Inconsistent steering feel

- Wandering under braking

- Shake that worsens over time

These components are safety-critical and should never be ignored.

Sticking Brake Calipers

A seized or slow-returning caliper piston causes uneven braking force. One wheel may grip harder than the other, pulling the steering rack and creating vibration or directional instability.

4. The 2026 Diagnostic Checklist

Step 1: Visual Inspection

Technicians look for:

- Blue or purple discoloration (overheating)

- Surface cracks

- Heavy rust ridges along the rotor edge

These signs indicate thermal stress or prolonged neglect.

Step 2: Measuring Rotor Runout

Using a dial indicator, runout is measured in thousandths of an inch. Anything beyond manufacturer specifications can cause noticeable vibration.

Step 3: Hub Surface Preparation

Even a new rotor can fail if installed on a dirty hub. Rust buildup behind the rotor creates immediate runout and premature DTV.

5. Prevention and News: Staying Smooth in 2026

Choosing the Right Rotor Material

- Carbon-ceramic: Excellent heat resistance, limited vibration, high cost

- Slotted/drilled: Better gas and heat management, but not immune to DTV

- High-carbon cast iron: Best balance for daily driving and vibration resistance

News Alert: Brake Dust Regulations

New 2026 environmental regulations targeting low-copper brake pads are changing friction material formulas. While eco-friendly, some early compounds increase rotor wear, making correct pad-rotor pairing more important than ever.

Conclusion: Restoring Your Driving Confidence

A steering wheel that shakes when braking is never something to ignore. It is a direct message from your vehicle’s safety systems that braking forces are no longer being applied evenly. Whether the cause is a sticking caliper, worn suspension bushings, or the early signs of warped brake rotors, timely diagnosis protects both your wallet and your safety.

By understanding the mechanics behind the vibration, you can approach repairs with clarity—knowing whether the solution is a straightforward rotor replacement or a deeper suspension overhaul. Smooth braking isn’t just about comfort; it’s about maintaining control when it matters most.

## Expert Resources & Further Reading

– NHTSA …

– ASE …

– Brembo …

– Car and Driver …

Editorial Note:

This content is provided for educational and diagnostic reference only…

Expert Resources & Further Reading

For readers who want deeper technical context and authoritative safety guidance, the following expert resources expand on the diagnostics and mechanical principles discussed in this guide:

- NHTSA – Consumer Guide to Brake Safety

A government-backed overview of brake system warning signs, inspection intervals, and safety risks associated with vibration, pulsation, and uneven stopping performance. - ASE – Understanding Brake Pulsation and Vibration

Professional-level explanations used in technician certification training, detailing how rotor runout, disc thickness variation, and caliper issues translate into steering wheel shake during braking. - Brembo – Technical Guide to Disc Thickness Variation (DTV)

An engineering-focused resource that explains how microscopic rotor thickness changes—not visible “warping”—create brake vibration, pulsation, and steering feedback under load. - Car and Driver – How to Diagnose Steering Wheel Shakes

A practical, road-tested breakdown connecting driver-reported symptoms with real-world mechanical causes, especially useful for distinguishing brake-related vibration from suspension or tire issues.

Frequently Asked Questions (FAQs)

How long can I drive with a shaking steering wheel before it becomes dangerous?

There is no fixed mileage or time window. Once steering wheel shake appears during braking, the braking system is already operating outside normal tolerances. Continued driving can accelerate rotor damage, worsen suspension wear, and increase stopping distance unpredictably.

Does resurfacing rotors fix steering wheel shake permanently?

Rotor resurfacing can reduce vibration only if disc thickness variation remains within manufacturer limits. In many modern vehicles, rotors are already near minimum thickness, making replacement a more reliable long-term solution than machining.

Can uneven wheel torque cause steering wheel shake after brake service?

Yes. Improper lug nut torque—especially when applied unevenly with an impact wrench—can distort the rotor hat against the hub. This often causes vibration shortly after brake service, even when new parts are installed.

Why does steering wheel shake sometimes return after new brakes?

Recurring vibration usually indicates that the root cause was not corrected, such as rust on the hub surface, a sticking caliper, or worn suspension bushings. New pads and rotors alone cannot compensate for underlying mechanical imbalance.

Can alignment issues cause shaking only when braking?

Wheel alignment by itself rarely causes braking-only vibration. However, misalignment combined with worn suspension components can amplify steering feedback during deceleration, making alignment a contributing—not primary—factor.

Should rotors always be replaced in pairs to prevent vibration?

Yes. Replacing rotors in pairs ensures balanced braking forces across the axle. Installing a new rotor on one side and leaving a worn rotor on the other can create uneven braking torque and steering pull.

Does brake vibration affect ABS or traction control systems?

Yes. Uneven braking forces can trigger erratic wheel speed readings, causing ABS or traction control systems to activate unnecessarily. This may feel like pulsing or reduced braking response during normal stops.

Can weather or corrosion cause steering wheel shake when braking?

Corrosion buildup on rotors and hubs—especially in humid or coastal environments—can create uneven contact surfaces. This often leads to vibration after long parking periods or seasonal vehicle storage.